Picture this: You are running a growing glass processing business, and every day feels like a balancing act –managing stock, scheduling production, and ensuring deadlines are met. Now, you have heard that an ERP system could transform your operations, but what about the pricing? That is where things get tricky. Why are the prices so different between providers? Are there hidden fees waiting to surprise you? And how can you be sure it’s worth the investment?

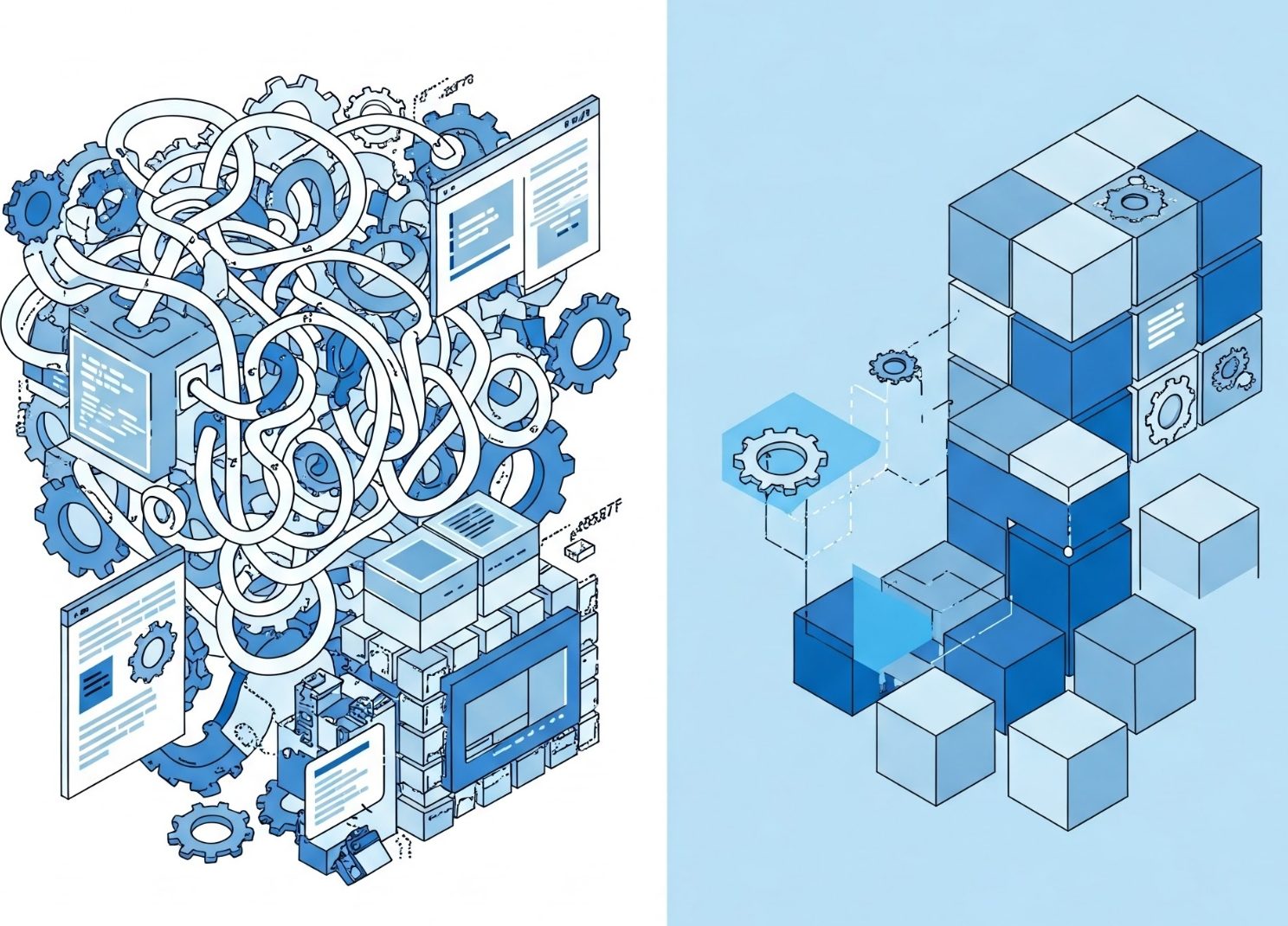

Navigating ERP pricing can feel like solving a puzzle without all the pieces – frustrating and time-consuming. For glass processors, the stakes are higher: the right ERP system does not just streamline operations; it can transform your bottom line.

Noel Bellen, Sales Manager at Synerglass-Soft, has spent time guiding businesses like yours through this process. With deep expertise, Noel understands what it takes to choose an ERP solution that not only meets your needs but fits your budget.

In this guide, we will break down the key components of modular ERP pricing, uncover hidden fees, and equip you with the tools to make an informed decision.

Why Modular ERP pricing can be complex for glass processors

As a glass processor, your business operates in a unique space, with challenges like managing complex workflows, maintaining high-quality standards, and optimizing resource use. ERP systems help streamline these processes, and modular ERP solutions offer an even additional advantage: flexibility.

Modular systems allow you to select only the features your business needs, scaling up as you grow. This flexibility gives you the chance to scale their systems, but it also makes pricing more dynamic and, at times, harder to grasp.

Key questions to consider:

- How does the number of modules or users impact pricing?

- Are there startup fees or maintenance costs?

- What features are included, and do they align with your business goals?

Understanding what drives pricing will help you optimize your investment while ensuring you are investing in the right tools. And what does that mean for pricing? Let’s explore.

Breaking down modular ERP pricing: what every glass processor should know

When you are considering an ERP system for your glass processing business, the price can be a major factor in your decision-making process. ERP pricing, particularly for modular solutions, varies greatly based on the specific needs of your business. Let’s break down the key elements that impact modular ERP pricing and explain how you can avoid unexpected expenses while ensuring they get the best value.

3 key pricing factors for modular ERP systems glass processors need to know

Factor #1: Number of modules

Modular ERP systems are designed with flexibility in mind, allowing businesses to select only the specific functionalities they need. These functionalities, known as modules, focus on particular areas like production planning, inventory management, or optimization. Each module is priced separately, meaning the number of modules you choose directly affects the overall pricing.

Some ERP providers offer bundled pricing models where adding more modules reduces the price per user, making it more cost-effective to expand functionality. For example, you may find that bundling stock and production management modules is cheaper than purchasing them separately but also simplifies system integration.

With Symbiose, the more modules you select, the lower the per-user price becomes, thanks to a bundled pricing structure. This allows to invest in a comprehensive system while still managing costs effectively.

Factor #2: Number of users

Pricing also depend on how many employees will use each module. For example, you might need five user licenses for a production module but only two for a sales module. This variation adds complexity to pricing but allows you to control costs by allocating licenses strategically.

Each module in Symbiose allows tailored user allocations. For instance, your production team may need more licenses for the Planning & Production Management module, while your admin staff might only need access to Order Management and Admin modules.

By aligning licenses with actual usage, businesses can optimize investments without paying for unnecessary access.

Factor #3: Level of features

The complexity and depth of the features you choose can also influence pricing. Basic modules might cover essential tasks like order management, while advanced modules could include features like real-time analytics, machine integration, or automated reporting. Keep in mind that while more advanced features might cost more, they can also deliver significant ROI through increased efficiency.

Choosing a more advanced set of functionalities and options will result in a higher price, reflecting the added value these features bring to your operations.

Tip: Start with the features you need now, and expand as your operations grow. Advanced features can deliver excellent value if they solve pain points like production delays or excessive waste..

While these 3 factors influencing the price are part of the investment, they can vary depending on your needs and the configuration of the modules you choose. It is important to ask the right questions to understand what is included in the price and what might come with an additional cost. The key is that not all costs are guaranteed – some may be optional or bundled into the overall pricing, so understanding what’s included can help you plan your budget more effectively.

Now that we have covered the primary influencing factors, let’s look at additional hidden fees you should account for.

Hidden fees of modular ERP systems and how to avoid them

Understanding upfront investments is critical, and it is just as important to anticipate hidden fees that may arise. While the price of the modules may be straightforward, there are additional fees that could influence your overall investment. Some of these costs may not always be applicable, depending on your specific circumstances and the package you choose. Here are the most common ones to consider:

1. Startup fees

Many ERP systems, including modular ones, have initial fees that businesses often overlook. These are often a combination of several factors:

- The the main platform:

Depending on the ERP provider, the main platform pricing may be structured differently – some systems include it in the prices, while others, like Symbiose, charge it as a recurring fee.The main platform is a crucial part of the system’s overall pricing structure. This is the core system on which all the other modules are built.

Think of it as the base of a building. No matter how many floors (modules) you add later, you first need a sturdy and reliable foundation. - Module configuration:

While the modules themselves are priced individually, each of them needs to be set up to align with your business processes. For example, configuring an “Order Management” module might involve customizing it to match your pricing rules or approval workflows.

In many cases, these configurations involve a tailoring fee rather than a simple setup fee. A tailoring fee covers adjustments such as incorporating your company’s price lists, workflows, and even branding elements like your logo on documents and labels. This ensures the system works seamlessly within your existing processes.It is important to note that not all implementations incur a tailoring fee. In some cases, basic setup may be included in the overall pricing while for more complex needs, there could be an additional tailoring fee. This depends on the scope of your business requirements. - Data migration:

Transferring existing business data – such as order history, stock records, and customer data – can range from simple to complex, depending on your current system. While some providers include this cost, others may charge separately for extensive migration needs. - Employee training:

To ensure a smooth implementation, your team needs proper training. And training is another potential fee to consider, but it is not always a separate expense. Some ERP providers may include basic training as part of the package, while more extensive training or training for a large number of users could incur an additional fee. The price of training depends on the number of users, the modules you are implementing, and the level of training required. Otherwise, training often comes with the installation fee and is charged seperately with software, such as with Symbiose.

It is important to discuss upfront whether training is included or if it will be an additional cost. Some companies may include training in the package, while others may offer it as an add-on.

2. Implementation and setup fees

Implementing an ERP system goes beyond purchasing the software. Setup and configuration are necessary to tailor the system to your unique business processes. Depending on the complexity of your operations and the customizations needed, setup fees can vary significantly. In most cases, such as with Symbiose, implementation fees include installation, configuration, customization, and training, providing a comprehensive approach to setting up the system.

Note: While some ERP providers include basic setup in their offerings, additional custom configurations may come at an extra cost.

2. Ongoing maintenance and updates

While your initial ERP investment may cover setup and training, you should also budget for ongoing maintenance. For perpetual software, maintenance costs typically range between 15% and 20% of the purchase price. This includes regular software updates, bug fixes, and technical support to ensure your ERP system runs smoothly and adapts to your evolving business needs.

For software using a subscription model, ongoing maintenance and updates are generally included in the monthly license fee, eliminating the need for separate maintenance charges.

Tip: Confirm with your ERP provider whether ongoing support and updates are included in the license fee or if they will incur additional charges down the line.

3. Downtime costs

During the implementation phase, you might face some disruption to your daily operations. This could lead to indirect costs, such as reduced productivity or operational delays, especially if the system requires time to be fully integrated or if employees need time to get used to the new software.

Tip: While downtime is sometimes unavoidable, it’s important to plan for it. Work with your provider to create a timeline that minimizes disruption and ensures a smooth transition. For instance, you could plan the implementation during weekends or during periods when production is slower. This helps reduce the impact on your operations and allows your team to get comfortable with the new system without affecting your output too much.

4. Add-ons and integrations

If your company requires additional features or integrations with other systems – such as linking to accounting software or other industry-specific tools – this could result in extra costs.

Many ERP systems, including Symbiose, offer documented APIs, enabling seamless integration with virtually any application that supports APIs. This flexibility means the connection between your ERP and other software can be arranged by the editor of the other software, a partner, or the ERP provider.

These add-ons and integrations are not mandatory; they depend on your specific needs. By choosing only the add-ons that align with your operations, you can avoid unnecessary expenses.

Tip: Before making your purchase, identify which modules are essential for your business and which are optional. Ask the provider about bundling options, which could offer a more cost-effective solution for your needs.

Once you understand the breakdown of costs, the next step is determining whether the investment will provide long-term value for your business.

Evaluating modular ERP pricing: 3 steps to make an informed decision

When evaluating ERP solutions, it’s important to go beyond comparing prices. Here are three steps to help you make an informed decision:

- Step #1: assess your needs: Define the processes your ERP must address, like production scheduling or inventory tracking.

- Step #2: compare features and costs: Evaluate how well the features of each ERP system align with your business goals. Look at both the immediate benefits and the long-term value.

- Step #3: request transparent pricing: Ensure proposals detail setup fees, licensing, and maintenance costs.

Modular ERP systems like Symbiose are designed for the glass industry, addressing unique challenges such as production management and machine integration. However, comparing other options is essential to find the best fit for your business.

When comparing ERP systems, focus on:

- Investment vs. ROI

- Scalability

- Customization

- Customer support and training

By taking the time to evaluate multiple options, you will find a solution that not only meets your current needs but also adapts to your business as it grows.

From pricing to implementation: your next steps for ERP success

Choosing the right modular ERP solution does not have to be overwhelming. By understanding pricing factors like modules, users, and features – and planning for hidden fees – you can make an informed decision that delivers lasting value.

At Synerglass-Soft, we have spent over 30 years supporting glass processors with tailored solutions. Our modular ERP system, Symbiose, is built specifically for the glass industry, offering scalability and features designed to optimize your operations and grow with your business.

Your next step? Schedule your free consultation today to discover how Symbiose can simplify your operations and drive growth in your glass processing business.