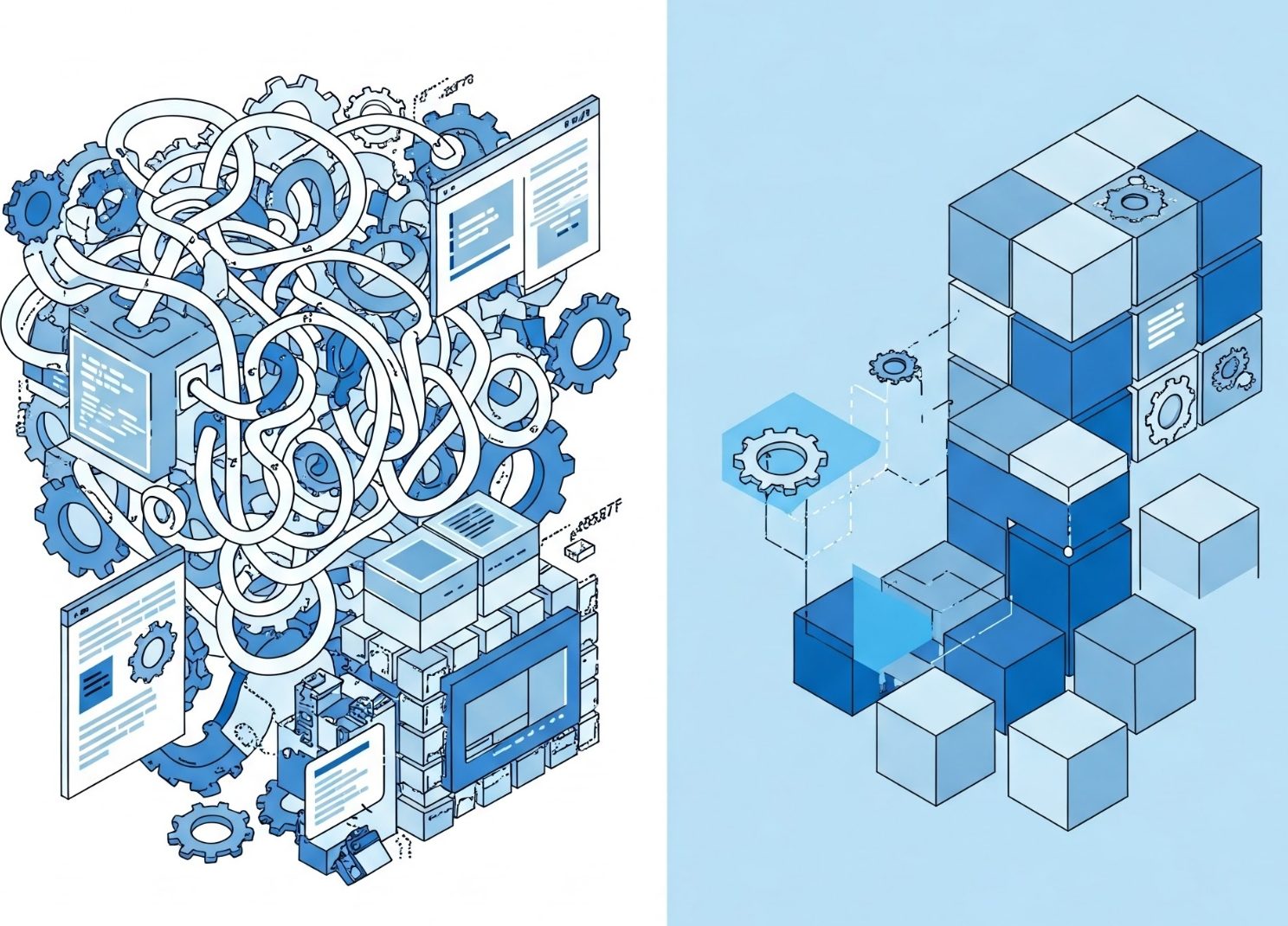

Let’s be honest – order management can feel like a constant uphill battle for glass processors. You are juggling multiple orders, managing stock levels, and coordinating between departments. When these processes are not smooth, the result is lost time, higher costs, and frustrated customers. But the real game-changer lies in your order encoding process – this critical step can make or break the efficiency of your operations.

We have worked with countless glass processors who have been through these same frustrations. They have told us how long it can take to manually input orders, fix errors, or track down information between departments. At Synerglass-Soft, our 30 years of expertise in the field means we understand these challenges deeply and have developed strategies to simplify these processes.

In this article, we will explore these proven and actionable strategies to make order encoding faster and easier, whether you are using manual methods or considering implementing a specialized tool like SynerOrder, a part of our modular software solution, Symbiose. By the end, you will walk away with practical tips to optimize your workflow and reduce order-related errors.

Why Does the Order Encoding Process Matter So Much?

Before we dive into the specifics, what is order encoding? It is the process of inputting the details of each order into your system, ensuring every specification, from the type of glass (e.g., laminated, tempered) to the custom notches, holes, or crosspieces, is correct. This critical step can make or break your business. If the order encoding process is slow or prone to errors, it can have a domino effect, leading to delays, rework, and dissatisfied customers.

Imagine this: a large custom glass order comes in, but one critical detail is entered incorrectly. The production team proceeds with the wrong specifications, and by the time you catch the error, it is too late. Now, your team has to restart the entire process, wasting valuable time and materials. Even worse, your customer is frustrated by the delay, which can permanently damage your reputation.

These are the real consequences of poor order encoding. Let’s look at how inefficient order management impacts your business:

- Lost time and productivity: Manual order entry is time-consuming, and any rework due to mistakes slows the entire production process.

- Increased costs: Errors in order encoding mean wasted materials, extra labor, and potential rush fees to meet deadlines after fixing a mistake.

- Customer dissatisfaction: Your customers want a smooth experience when buying from you. If there are any issues with orders, delays, or deliveries, it can really damage their trust and drive them toward competitors.

For glass processors, every minute counts. Making sure you have a good order management system in place not only makes the production run more smoothly but also improves relationships with your customers.

Balancing Speed and Accuracy

The goal of improving order management is not just to make things faster – it is to ensure that speed does not come at the cost of accuracy. To get this balance right, you need to make your processes more efficient and use tools that help you work smarter, not harder.

Here is why it is worth the effort:

- Fewer delays: With a more efficient system, orders are processed and communicated faster, keeping your production line moving.

- Happier customers: When orders are accurate and delivered on time, customer satisfaction goes up. A satisfied customer is more likely to become a repeat customer.

- Cost savings: Reducing errors and manual rework saves both time and money, allowing you to invest those resources to better use in your business.

3 Key Steps to Speed Up Order Encoding and Eliminate Errors

You do not have to make your order encoding process more complicated to make it better. In fact, by putting a few key strategies in place, you can see significant improvements in both speed and accuracy for your glass processing business. Here is how:

1. Optimize Data Entry to Minimize Errors

Manual data entry is one of the most common causes of costly mistakes. Whether you’re relying on handwritten notes or spreadsheets, the risk of errors is high. The solution? Simplifying the process.

With an order management tool like SynerOrder, your team can benefit from a highly user-friendly interface that reduces the risk of human error and streamlines the data entry process. Working on an intuitive design ensures accurate order input with less effort, meaning less time spent on corrections and more time for productive work.

Example: Rather than having your team manually transfer order details from emails or paper forms, you could use a digital system that allows customers to submit orders directly into your system, filling in the necessary fields. This helps to reduce the chance of any information being missed or entered incorrectly.

2. Streamline Your Order Formats

In glass processing, no two orders are exactly alike. However, it is important to have a consistent approach to capturing key technical specifications to avoid confusion and mistakes. While it is rare to have identical orders, using a structured template to capture the necessary details – such as the type of glazing (e.g. insulated glass, double glazing), glass thickness, custom notches, holes, or any special treatments – ensures accuracy and helps your team move quickly.

If everything is formatted the same way, it will be quicker for your sales, production, and logistics teams to input and review orders.

Example: A digital order form that allows users to select specific glass types or input unique measurements for custom cuts can help reduce the chance of missing important details or making mistakes when entering data. Having a structured template like this allows your team to process orders more quickly while ensuring the right specifications are captured each time.

3. Centralize Order Information

It is not uncommon for order information to get scattered across different departments. Sales has one version, production has another, and logistics is left trying to track it all down. If you centralize your order management system, everyone’s working from the same info, which is updated in real time.

Using a centralized platform means that any changes to an order are reflected immediately. This means there is no lag in communication between departments, which reduces bottlenecks and makes the whole process more transparent.

Example: Use software that allows your team to access orders from a single platform, so everyone can see the latest updates. That way, if a customer makes changes to their order, production and logistics can adjust right away, without lots of emails or calls back and forth.

Maximizing the Potential of Technology in Order Management

While you can start improving order encoding by making process changes, using technology can really take it to the next level. Many glass processors are switching to modular software solutions, like Symbiose, to boost their order management systems.

For example, Symbiose, our modular software suite specifically built for the glass industry, includes SynerOrder, a tool designed to automate and centralize the order encoding process. This reduces the risk of human error and speeds up workflow, ensuring that all departments work from the same accurate, real-time data.

Choosing the right technology is not just about minimizing mistakes. It is about empowering your team with tools that enhance efficiency and customer service. While we have built SynerOrder based on common challenges we have seen in glass processing, the most important thing is to find the tool that best fits your specific needs.

Take Control of Your Order Management Today

Order encoding does not have to be a tedious, error-prone process. By automating data entry, streamlining your order formats, and centralizing information, you can make your order management system more efficient straight away.

If you are ready to explore new ways to optimize your process, consider solutions like SynerOrderby Symbiose, a tool specifically designed for glass processors to reduce human error and simplify workflows. Whether you choose SynerOrder or another tool, the key is finding the right solution that fits your business and allows you to streamline your operations.

Want to see how SynerOrder can optimize your order management? Schedule a demo with us today and discover how it fits your unique business needs.