If you are in the glass processing industry, you have probably dealt with complex workflows, frequent errors, and tight delivery schedules that can hinder profitability. These issues are frustrating, but the good news is that they can be solved efficiently with the right solution: modular software.

We understand how overwhelming it can feel when your systems no longer meet the demands of your business. Drawing from years of experience working with glass processing companies, we know what it takes to solve these challenges efficiently. Modular software can offer the flexibility and scalability needed to adapt to your unique business needs.

In this article, we will explain what modular software solutions are and how they can specifically address your unique challenges. You will learn how a modular system can adapt to your business needs and grow with you over time, making your operations smoother and more efficient without unnecessary complexity.

What Are Modular Software Solutions and How Do They Work?

Modular software is a set of interconnected, customizable systems where individual components, or modules, can be independently selected and added based on your specific business needs. In the glass processing industry, this might mean a system that can manage everything from raw material tracking (e.g., tracking batches of float glass) to production scheduling (e.g., aligning the cutting schedule with production rates) and quality control (e.g., monitoring the thickness, strength, and finish of the processed glass).

Each module works independently, but they all integrate seamlessly to give you a comprehensive view of your entire production line. For example, a cutting order management module can track the dimensions and specifications of glass sheets. Another module might manage stock and inventory (e.g., glass stock, consumables like cutting blades, and other raw materials). You could also have an optimization module to help you get the most out of your glass sheets, minimizing waste and improving material usage. The beauty of modular solutions lies in their flexibility – you can add or remove modules as your needs evolve.

Traditional software systems offer a comprehensive package with pre-built functionalities that cater to various needs. However, these one-size-fits-all solutions can sometimes lack the flexibility required for businesses with unique workflows.

Why Choose Modular Software for Your Glass Business?

Tailored Flexibility for Your Operations

One of the best things about modular software is that it can be tailored to suit your needs. With modular software, you do not have to change your business to fit a one-size-fits-all system. You can build a system specifically designed to fit your operations. In the glass industry, where production processes vary widely between companies, this level of flexibility is invaluable.

The glass processing industry is anything but standard. From float glass to laminated, tempered, and insulated glass, the complexity of production requires specialized tools that can adapt to each specific type of glass product. A modular software solution allows you to tailor each component to fit your unique requirements. Whether you need to streamline cutting line operations (e.g., optimize the use of raw glass sheets), track scrap rates (e.g., monitor waste during cutting or grinding), or optimize material usage (e.g., better manage glass thickness variations), modular software can be designed to address these specific challenges.

Save Money

In addition to flexibility, modular software can also help you save money in the long run. Instead of buying a full software package that includes features you might never use, you can choose the modules that are relevant to your business. This approach not only reduces the initial costs but also cuts down on ongoing maintenance expenses, as you will not need to worry about updating features that do not apply to your business.

For example, let’s say your glass processing company is expanding its product line. With a modular system, you can add new modules for managing different production processes without paying for unnecessary functionalities from the start. This means you can manage your budget more effectively as your business grows.

Additionally, as your business evolves, you can invest in new modules when needed, rather than having to replace the whole system. This scalability can save you a lot of money over time, ensuring you get the best return on your investment.

Not only can modular software save you money, but it also integrates easily with your existing systems, making your business more efficient.

Integrate with Your Existing Systems

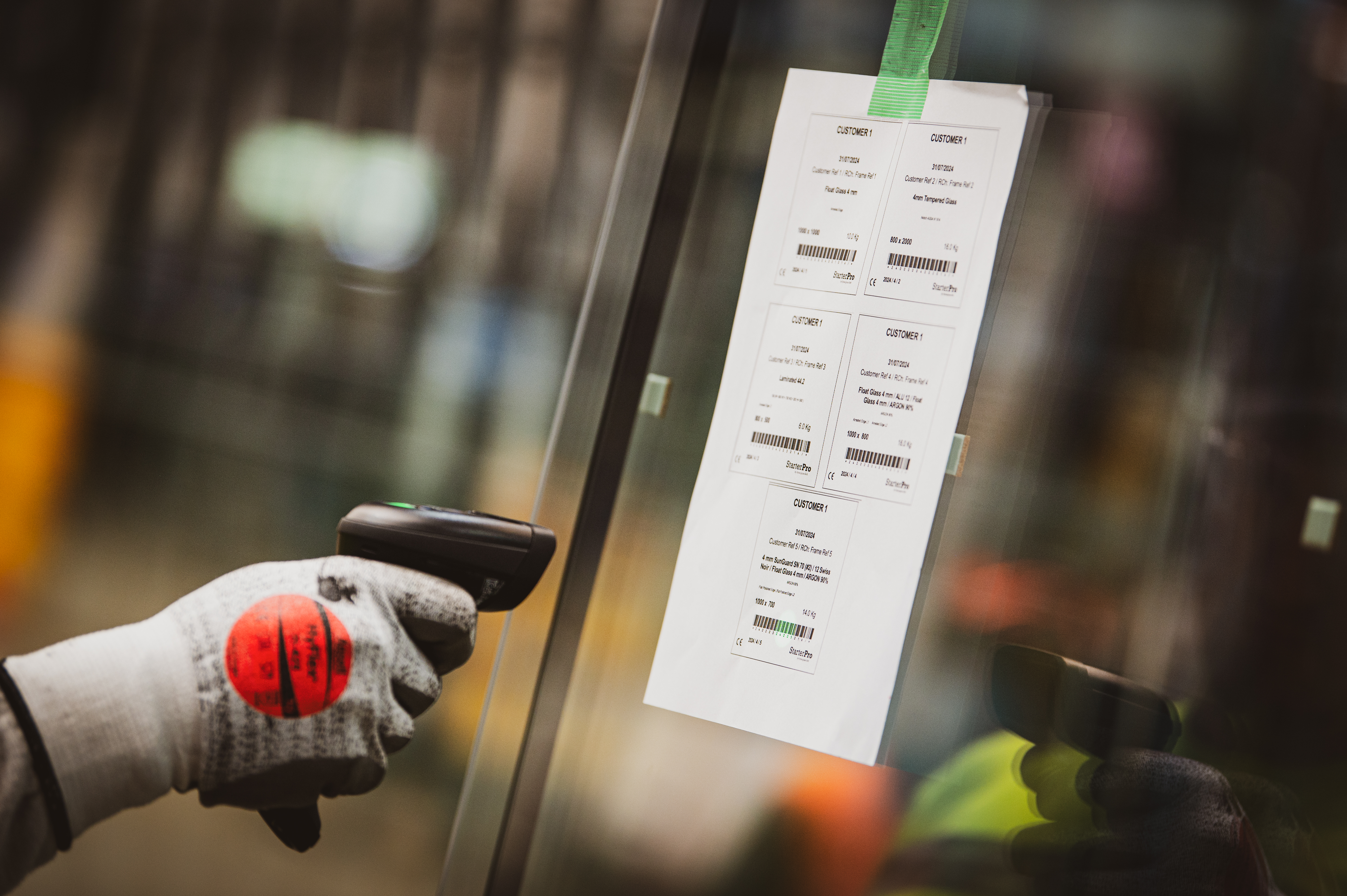

In the glass processing industry, businesses often rely on specialized equipment and tools, such as CNC cutting machines, glass cutting tables, and automated glass handling systems, to drive production efficiency. Modular software solutions are designed to integrate seamlessly with these existing systems, ensuring smooth communication across your entire operation.

For instance, if you already use a CNC (Computer Numerical Control) glass cutting machine for precision cutting, a modular software solution can connect to it, automating data exchange. This means you don’t need to manually enter machine data – saving time, reducing errors, and ensuring your production schedules stay on track.

On top of that, the ability to integrate with other systems means you can use the best tools available in the market. Whether it is accounting software, supply chain management systems, or customer support platforms, modular solutions can provide a unified experience that makes everything more efficient and effective.

Make Things Easier for Your Team

A modular approach can make a big difference in how users experience the software. Modular software allows users to customize their dashboards and workflows, which means it can meet the needs of different employees in different roles within the company. This makes the software easier to use and can also help boost productivity.

Imagine a production manager who only needs access to specific metrics and reports to keep an eye on production efficiency. With a modular system, they can adapt their interface to focus on what matters most to them, which allows for faster decision-making and better operational efficiency.

Additionally, giving users a personalized experience can get them more engaged and satisfied. When employees can use a system that meets their specific needs, they are more likely to embrace the technology and use it effectively, which ultimately leads to better business results.

Scalability for Growing Businesses

Another key benefit of modular software is its scalability. As your business grows and your operational needs evolve, modular systems can grow with you. You can start small with essential features and, as your business grows, easily expand by adding new features. This means that your software can grow in line with your company’s changing needs, without the hassle of a full system overhaul.

For example, you could start with modules for inventory and order management. As your operations get more complex, you can easily add features like production monitoring or optimization. This gradual approach helps make sure that your software keeps serving your business at every stage of its development.

Now, let’s dive into how modular software specifically benefits daily operations in glass processing.

How Modular Solutions Improves Daily Operations for Glass Processors

The real question many business owners have is: “How will modular software solutions actually improve my day-to-day operations?” Think of modular software as building a puzzle piece by piece. You start with the parts that solve your most pressing problems and expand the system as new challenges arise. Let’s break this down.

Help You Streamline Your Processes

A key advantage of modular software is its ability to streamline your processes. However, integrating modular software into existing workflows can come with challenges, such as initial staff learning curves and the time required to configure modules properly.

By combining different modules that are designed for your specific operations, you can get rid of redundant tasks. Imagine automatically syncing inventory data with your order processing system, eliminating the need for manual data entry. This makes the whole process more efficient and reduces the risk of mistakes.

Improve Communication Across Teams

In addition to streamlining processes, modular software also improves communication across teams, helping departments work together more efficiently.

For instance, if your Sales team can see at a glance what is going on in production and what stock is in, they can set realistic expectations with customers and avoid promising more than you can deliver. This improved communication not only makes internal operations more efficient but also leads to happier customers.

Empower You to Make Better Decisions

Data can transform your glass processing business by providing valuable insights. Modular software gives you access to analytics tools that help you understand how your business is performing. If you look at how data is changing over time, you can identify bottlenecks, monitor key performance indicators (KPIs), and make informed decisions that drive improvement for your business.

For example, if you notice a slowdown in production during specific shifts, you can look into it and make changes to make sure you have the right number of staff or processes in place.

Help You Adapt Quickly to Industry Changes

The glass industry is constantly evolving, with new techniques, technologies, and regulations shaping the landscape. A modular solution enables businesses to adapt quickly to these changes. Whether it’s adopting new processing methods, complying with updated safety standards, or responding to shifts in customer demand, modular software allows you to stay ahead of the curve.

For example, if there are new regulations around energy efficiency or safety standards, you can easily integrate new modules that help your company comply, ensuring you don’t fall behind

What Should You Know Before Investing in Modular Software?

Before jumping into any software solution, it is important to assess your current needs and future plans. Modular systems are flexible, but it is important to make sure you implement them in a way that does not disrupt your workflow. Here are some points to keep in mind:

- Start with your pain points: Focus on the areas of your business that are causing the most hassle – it could be order management, production monitoring, or inventory management. Start with the basics and add more modules as you need them.

- Ensure ease of integration: A good modular system will fit into your current workflow without forcing major changes, allowing your team to adjust at a manageable speed.

- Training and support: Any new system will take time to learn. Make sure the software provider offers proper training and ongoing support to help your team make the most of the tools.

The key is to take it one step at a time, ensuring that each step aligns with your business’s specific needs. Start small, tackle your immediate problems, and expand as your operations evolve.

When Modular Software May Not Be the Best Fit

While modular software is great for flexibility and scalability, it might not be the best fit for every business. If your company has highly standardized operations and little need for customization, a simpler software solution might meet your current needs. However, even for standardized processes, modular software can still offer flexibility in adapting to future changes or expanding your offerings.

For instance, a glass manufacturer specializing in tempered glass for automotive applications with a well-established production line might find that a simpler, one-size-fits-all software package is all they need. With standardized cutting, shaping, and tempering processes that follow a set schedule and minimal variation in order types, they may not require the added complexity or cost of a modular system. The main benefit of modular software is its adaptability, but for businesses like this, the customization it offers may not justify the extra investment.

Additionally, businesses that have relatively simple processes and are not planning to scale or diversify significantly in the near future may not benefit from the extensive features offered by modular systems. For example, a glass fabricator focused on producing standard glass shapes might not need the specialized features of a modular ERP system. In such cases, a more straightforward software package can handle the basic functions – inventory, order management, production tracking – without the need for additional customization or modules.

Despite these limitations, for businesses that need to integrate with multiple systems, modular software can still be a great way to unify operations.

Is Symbiose the Right Modular Solution for Your Glass Business?

One example of a modular software solution specifically tailored for the glass industry is Symbiose. With its flexible modules for production management, optimization, order processing, and more, it is designed to grow with your business and meet your evolving needs.

By using Symbiose, you are not just getting software; you are gaining a partner who is invested in your success. We are always working to improve our offerings and help your business reach its full potential because we are committed to continuous improvement and customer satisfaction.

Ready to Take the Next Steps with Modular Solutions?

In this article, you have learned about the advantages of modular software solutions for your glass processing business. You have seen how a modular approach can make your business more flexible, help you work more efficiently, and support growth without the constraints of traditional software systems.

So, what is the next step?

- Reflect on your current challenges: Take a moment to think about the areas of your business where you are not as efficient as you would like to be or where you are facing limitations with your existing systems.

- Explore your options: Take a look at modular solutions like Symbiose, which can be tailored to suit your specific needs. Think about how a modular system can help you adapt and grow in an ever-changing industry.

- Engage with experts: Reach out to our team to discuss how modular software can transform your workflow. We are here to guide you in selecting the right modules that align with your business goals.

Ready to explore how modular software can transform your glass business? Reach out to us at sales@synerglass-soft.com for a personalized consultation to discuss your unique challenges and find the right solution, or schedule a demo to see Symbiose in action. Start your journey towards a more adaptable and efficient operation today.