As a glass processor, every day brings new challenges, such as making production more efficient while keeping up with customer demands and maintaining quality standards. Whether you are managing a range of glass products, tracking inventory across multiple production lines, or dealing with unexpected order changes, these issues can cause bottlenecks, costly mistakes, and missed deadlines. These challenges may leave you asking: How can I make sure my production process runs smoothly every day? And how can I stay competitive in such a fast-paced industry?

At Synerglass-Soft, our team brings decades of hands-on experience to the glass processing industry. Our Products Manager has been at the forefront of developing ERP solutions tailored for glass manufacturers. Drawing on his extensive knowledge of industry challenges, he has collaborated with countless customers to tackle issues like managing complex inventories and production schedules, and minimizing operational inefficiencies. This ensures that every system we design not only resolves industry pain points but also empowers businesses to uncover new opportunities for growth and innovation.

In this article, we will explore five ways the right ERP system can drive significant efficiency in your glass manufacturing process through practical examples and expert insights. By the end, you will have a clear roadmap for how ERP can benefit your business.

Understanding the Need for an ERP System in The Glass Industry

Glass processing is a highly complex, detail-oriented process, and with all those details to think about, it can be tough to keep operations efficient and cost-effective. From cutting, shaping and tempering glass to managing inventory, scheduling, and meeting tight deadlines, the everyday workflow can often feel like juggling a lot at once. Add to this the pressures of changing customer demands, a global supply chain, and high expectations for product quality – and it is easy to see how inefficiencies can quickly become expensive.

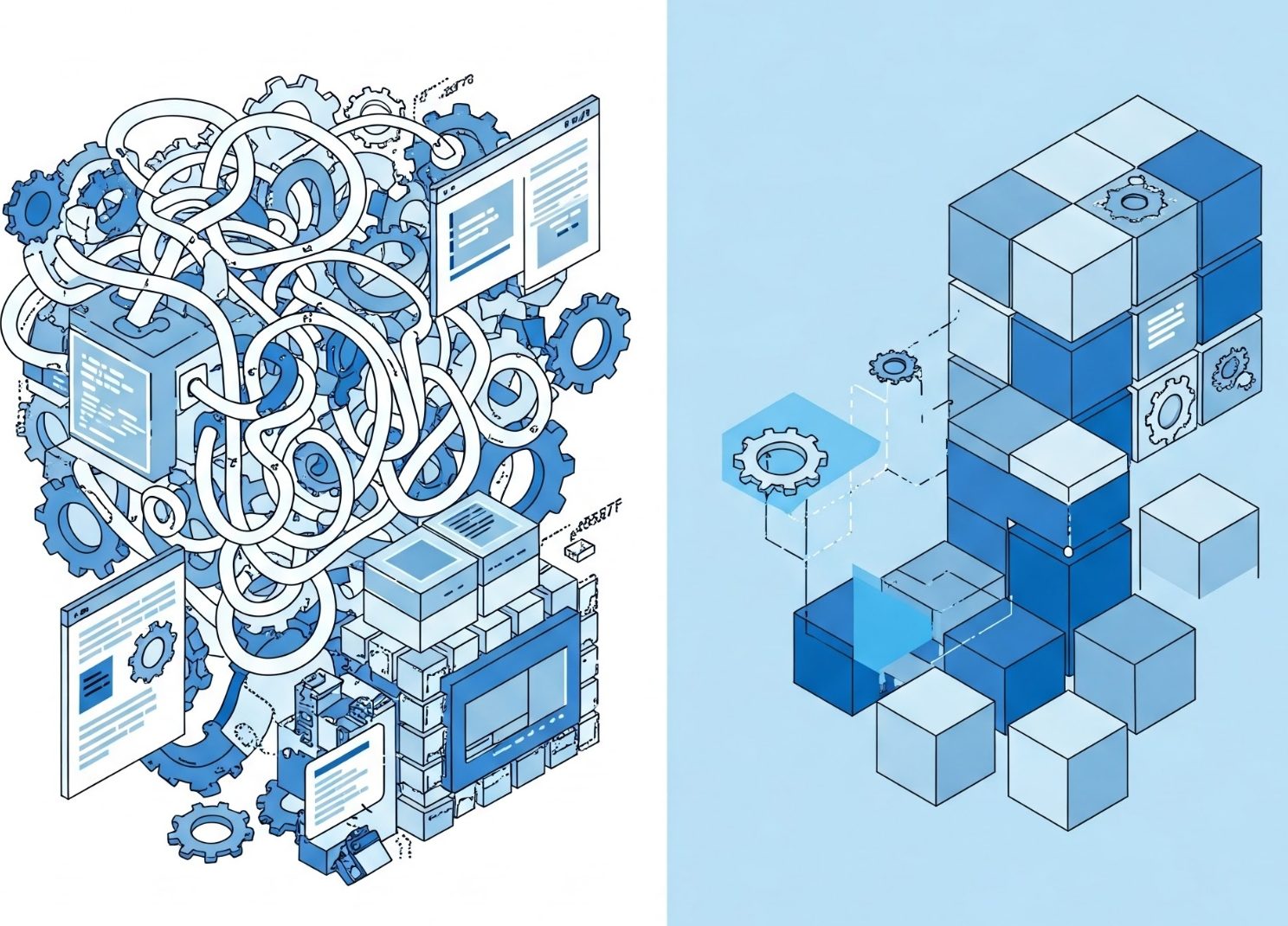

Traditional methods, such as relying on spreadsheets, manual entry, or disconnected software tools, can only take you so far. While they may work for smaller operations or during slower periods, as your business grows, they tend to show some gaps in your workflow. If you do not have the right tools, you might end up with poorly managed inventories, production delays, human errors, and missed opportunities for improvement.

This is where an Enterprise Resource Planning (ERP) system comes in. ERP is more than just a tool – it is an integrated solution designed to help you manage and optimize various aspects of your operations under one roof.

The right ERP system tailored specifically to the glass industry can address the unique challenges glass processors face, providing a centralized platform for everything from production management to customer orders, inventory tracking, and even financial management.

In the following section, we will dive into the five key ways an ERP system can help glass manufacturers like you streamline operations, reduce inefficiencies, and ultimately make more money.

1. Simplify Orders Management and Processing

In the glass manufacturing industry, no two orders are ever the same. Whether you are making tempered glass for skyscrapers, custom windows for a historical building, or specialized glass for cars – each order comes with its own set of complexities. Managing these specific requirements efficiently is crucial to maintaining customer satisfaction and ensuring the accuracy of every order.

A comprehensive ERP system centralizes all the details related to each unique order. It can manage everything from specific dimensions, and custom cuts, to more intricate features like notches, textures, and glazing configurations. By doing so, you can avoid mistakes and ensure that each customization is tracked, processed, and delivered without delay or confusion.

Managing custom glass orders accurately is essential for maintaining customer satisfaction.

Example:

Imagine a client ordering a batch of glass with highly specific notches and finishes. Without an ERP system, communication between sales, production, and inventory can get confusing. However, with an ERP, each team has access to the same detailed order specifications, reducing the chances of errors. This means the right materials are produced, the cuts are on point, and customer expectations are met.

2. Optimize Production Scheduling

Production scheduling is one of the most important and challenging tasks in the glass industry. With all the different orders – each with unique specifications, deadlines, and resource needs – it is easy to run into bottlenecks, missed deadlines, or unhappy customers.

An ERP system helps you take control by automating scheduling and optimizing resource allocation based on updated information. It ensures that your production schedule is always aligned with the latest order priorities, machine availability, and material levels. It also helps assign the right resources to the right jobs at the right time, ensuring that every project progresses according to plan.

How it works:

The ERP system uses real-time data to allocate tasks based on priority levels and available resources. It makes sure that important orders are finished on time without delaying other routine jobs. It also considers any machine downtimes, material shortages, or labor availability, automatically adjusting schedules as needed.

3. Manage All Inventory – Glass Materials, Accessories, and Hardware – with Precision

Glass processors work with a wide range of materials, from different types of glass such as laminated or insulated to various thicknesses, coatings, and finishes. But it is not just glass – other essential components like spacers, Georgian bars, intercalates, and hardware also play a key role in the manufacturing process. With so many different things to think about, it is easy for stock to get out of control. This can lead to shortages, overstocking, or production delays. If you don’t keep track of your inventory properly, it can cost you money. You might miss out on sales and end up waiting longer than you should to fulfill orders.

An ERP system provides visibility into inventory levels. This means that at any given moment, you can see exactly how much of each material – laminated glass, coatings, or hardware – is in stock. This feature not only ensures that the right materials are available for production but also allows for better forecasting and planning by tracking how materials are used over time.

How it works:

With an ERP system, inventory management becomes automated. When materials are used up or replenished, the system automatically updates stock levels. It also uses historical data to predict future material needs, ensuring that the right quantity of materials is ordered at the right time.

4. Improve Communication Across Departments

In the world of glass manufacturing, where things move fast, it is really important to be able to communicate easily between departments. This helps to keep the whole process efficient and reduces the risk of mistakes. If you do not share information across departments, you might miss something important, which could lead to mistakes, delays, and costly misunderstandings. An ERP system makes sure that everyone in the company is working from the same data, which helps to improve coordination and alignment throughout the production process. It integrates sales, production, inventory, and logistics, meaning information can flow easily between departments. Any changes made in one department – like an order update, a new production requirement, or a delivery change – are automatically reflected across the system.

Example:

In a glass processing plant, precise cutting instructions are crucial. Without an ERP system, these instructions are often written on paper and passed from the order entry team to the cutting operators. This can result in lost or misinterpreted instructions, leading to mistakes in production. For example, a cutting operator might misread or overlook a detail, resulting in wasted materials or delays. With an ERP system, all cutting instructions are digitized and integrated into the system. The operator can access the exact specifications directly on the system at the moment of cutting, ensuring accuracy and eliminating confusion.

5. Make Data-Driven Decisions with ERP Reporting

Making decisions without data is like flying blind. A glass processing ERP system consolidates data from sales, inventory, and production into easily accessible reports that you can use to refine operations.

While not every ERP system includes advanced Business Intelligence (BI) tools, most ERP solutions do offer essential reporting features that can be useful for day-to-day decision-making. BI tools are software applications that analyze and visualize data to uncover trends and insights. They can help you track production efficiency or identify recurring bottlenecks. With these insights, you can better understand how your operations are performing and make the necessary adjustments to meet customer demands and improve performance.

An ERP system usually brings together data from different departments, so users can create reports on important metrics. These reports give the insights needed to address immediate operational issues and anticipate potential problems.

Example:

Let’s say there’s a recurring bottleneck in production for custom orders with specific glazing or finishing needs. An ERP system’s BI dashboards can show sales by type of glass and margins, helping to identify the most popular and profitable products. For instance, if laminated glass brings higher margins, the production team can prioritize these orders. This allows for better resource allocation, smoother operations, and meeting customer expectations without delays.

How the Right ERP System Transforms Glass Manufacturing

The glass manufacturing industry faces a unique set of challenges, from managing complex custom orders to optimizing production and ensuring materials are always available when needed. An ERP system designed specifically for the glass industry can help manufacturers tackle these challenges head-on by streamlining operations, reducing errors, and improving overall efficiency.

With a comprehensive ERP system, businesses can automate key processes like order management, production scheduling, and inventory tracking. This empowers you to meet customer demands with greater efficiency and accuracy.

At Synerglass-Soft, we specialize in ERP solutions tailored to the glass industry. Whether you are exploring ERP for the first time or seeking to optimize your current setup, take the next step in your journey. Try our ERP Health Checklist to evaluate your current processes and the health of your IT systems. If you are ready to explore ERP solutions, we’re here to guide you through every step.